One of the most important aspects of accounting for manufacturing inventory is the distinction between the cost of conversion and the cost of goods sold. These two terms refer to different ways of measuring the expenses incurred in producing and selling goods. Understanding the differences and similarities between them can help managers and investors make better decisions about the performance and profitability of a manufacturing business.

What Is Production Management System? – Definition, Importance & Benefits

As mentioned, your conversion cost provides important insights into your budget. There are a few important ways in which you can use the information once you know all about conversion cost. Imagine an e-commerce company that wants to increase its conversion rate (the percentage of website visitors who make a purchase). The original checkout flow has multiple steps, including account creation, shipping details, and payment information. The company hypothesizes that simplifying the process will lead to higher conversions. Adopting lean manufacturing principles can streamline processes, eliminate waste, and optimize resource usage.

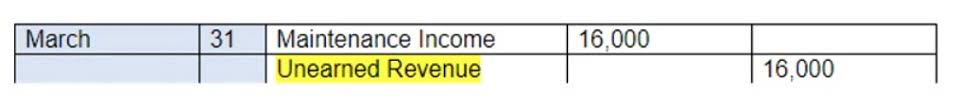

Omit ‘Indirect’ Costs

The greater the proportion of prime costs in total costs of a product, the more reliable is the cost estimate of the product. Conversion costs are the costs that are incurred conversion costs in converting direct raw material into finished goods and hence the name. In summary, conversion cost provides a granular view of production expenses, allowing businesses to optimize their processes and allocate resources efficiently. By understanding how it compares to other cost metrics, organizations can make informed decisions to enhance profitability and competitiveness. Remember, the journey from raw materials to finished products involves more than just numbers—it’s a dynamic interplay of labor, creativity, and strategy. Once costs can be classified by nature, these can be used to find the prime costs and conversions costs of a product.

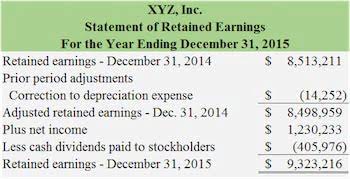

How to Record and Report the Conversion Cost in the Financial Statements?

- Remember, the journey from raw materials to finished products involves more than just numbers—it’s a dynamic interplay of labor, creativity, and strategy.

- Prime costs refer to the total cost of direct materials and direct labor.

- By including direct labor and manufacturing overhead, conversion costs provide valuable insights into production efficiency and cost structure.

- Calculating the cost of conversion accurately is essential for businesses to determine the overall production costs and make informed decisions.

They also help to allocate the costs of goods sold (COGS) and inventory valuation. Conversion costs are the expenses incurred in the manufacturing process to convert raw materials into finished goods. These costs include direct labor and manufacturing overhead costs but exclude direct material costs. The difference between the two cost classifications is that prime costs only relate to direct material and direct labor costs, while conversion costs only include direct labor costs and factory overhead costs. Conversion costs can be considered to layer on top of prime costs, where they are needed to convert raw materials into finished goods. In accounting, conversion costs represent the money spent on turning raw materials into finished products.

Real-World Impact of Conversion Costs

- By understanding these costs, you can better evaluate the profitability of your manufacturing processes.

- Conversion costs are essential for measuring efficiency and profitability in manufacturing processes, encompassing both labor and overhead expenses.

- Note that IAS 2 mandates the allocation of production overheads, entities cannot opt to exclude them from the cost of inventory.

- These narratives have provided us with valuable insights, demonstrating that cost reduction is not merely about cutting corners but about smart investments in technology, processes, and people.

- Conversion cost is a vital metric for manufacturing and production businesses.

Prime cost includes direct materials and direct labor, representing the direct costs of production. Conversion cost includes direct labor and manufacturing overhead, reflecting the costs to transform raw materials into finished goods. The key difference lies in net sales the inclusion of manufacturing overhead in conversion cost but not in prime cost.

- It further allows you to create multi-level bills of materials (BOMs) to improve your production and financial management.

- The first step was the integration of digital tools to automate routine tasks.

- It helps you invest in automated tools to reduce labour needs and overhead expenses.

- Let’s consider an example to illustrate the concept of conversion cost variance.

- Being aware of your business’s conversion costs helps in the assessment of its efficiency in converting raw materials into sellable goods.

- This report shows the costs used in the preparation of a product, including the cost per unit for materials and conversion costs, and the amount of work in process and finished goods inventory.

Why TranZact’s Digital Document Management System is Right for Your Business?

- How to use conversion cost for cost accounting purposes, such as assigning costs to products, inventory valuation, and variance analysis.

- Similarly, the direct labor cost of a single bicycle will include $10 paid to the assembly worker, $2 ($8 per hour / 4 bicycles) paid to the worker that paints the bicycles.

- Assume that there was no work in process inventory at the beginning and at the end of the accounting period.

- Through these examples, it is clear that technology is not just an enabler but a critical driver in enhancing conversion efficiency.

- Since the company produced 500 units of chairs per month, the conversion cost per unit of a single chair will be $6.

- It is easier to track the materials and conversion costs for one batch and have those costs follow the batch to the next process.

Management needs to understand its costs in order to set prices, budget for the upcoming year, and evaluate performance. By analyzing the conversion cost ratio and its components, businesses can gain valuable insights into their cost structure, identify cost-saving opportunities, and optimize their manufacturing processes. If it is not, such as just one or two conversions from 1,000 clicks, consider pausing the keyword. You see which of your campaigns have the lowest cost per conversion, preferably compared to high values for those conversions, and focus your efforts and budget on them.

1 Pricing Decisions

In summary, overhead costs are the silent contributors to Catch Up Bookkeeping a company’s overall expenses. Understanding their nuances, allocating them accurately, and optimizing their impact are critical for sustainable business operations. Remember that while direct costs are visible, overhead costs quietly shape the financial health of an organization.